SUMMARY

Even though the industry is at a nascent stage, India needs to be careful about e-waste problems arising from increased EV adoption

Learning from China will help India develop better battery recycling policies and reduce the price of EVs

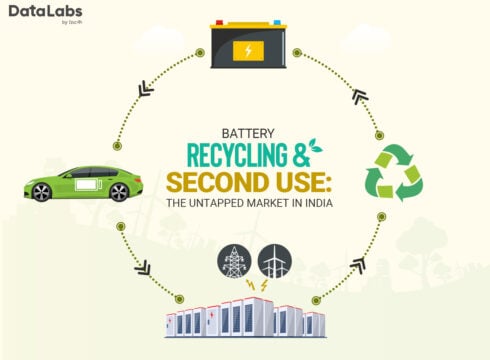

Battery recycling and second use of battery will open new business and employment opportunities for the automotive sector

Inc42 Daily Brief

Stay Ahead With Daily News & Analysis on India’s Tech & Startup Economy

China is leading the global electric vehicle market with over 1.18 Mn passenger EVs sold in 2019. It is slowly becoming Detroit of the EV world with its fast-paced manufacturing, high-end designs and also tie-ups with major players such as Tesla and others. In the initial years of EV adoption, China faced a huge problem in battery recycling, which only piled up as more and more people adopted EVs. The collaborative effort of smartphone manufacturers, major automakers and the Chinese government helped the country curb this problem before it got out of hand. And therein lies a lesson for India too as electronic waste and dead batteries will soon become a big issue in the Indian market as well.

In India, only 3,600 passenger EVs were sold in 2019, so the market is nowhere close to China. But India is preparing to transform 30% of automotive sales into e-mobility by 2030. To get there, it not only needs to create infrastructure but also prepare for the battery recycling problem from the very beginning stage. It will help to solve the e-waste problem and open new business opportunities in India.

Falling Battery Costs Fuel Electric Vehicle Demand

The cost of batteries has fallen continuously over the years just like any piece of technology and there have been advances in efficiency as well. This trend of dropping battery costs has helped reduce the market price of EVs. Since batteries account for up to 40% of an EV ‘s cost, India will see more penetration in EV demand when battery costs fall. Besides concentrating on developing battery cell and pack manufacturing, India needs to work on battery recycling as well

At the initial stage of EV adoption, battery swapping is gaining popularity but it’s not the ultimate solution for mass EV adoption. Some companies like Sun Mobility, Panasonic, Exicom, Lithium Power Pvt Ltd, SmartE and Amara Raja batteries are providing battery swapping services in India. With the development of fast-charging stations, battery swapping will fade away. However, battery recycling and the second use of battery will open new opportunities in the automotive industry in the coming years.

China Leads The EV Battery Market

In 2019, except Contemporary Amperex Technology (CATL), other companies in China struggled to increase their EV battery market share due to the tight competition in the market. China’s revised New Energy Vehicle policy also impacted the operations of local players. Nevertheless, the market conditions in China were good enough to secure a lead in the global EV battery market in 2019.

Overall, the major EV battery manufacturers are from China, Japan and Korea.

- China: CATL, BYD, Guoxuan High-Tech Co

- Japan: Panasonic, Automotive Energy Supply Corporation, Primeearth EV Energy

- Korea: LG Chem, Samsung SDI, SK Innovation

Sadly, there are no large EV battery manufacturing plants in India yet. Domestic production of batteries in India will reduce the cost of battery procurement for manufacturers, which can be passed onto the consumers.

The global EV battery market is expected to reach 384GWh by 2025. Hence, there is a huge opportunity for India to build its state of art battery technology.

EV Waste Poses A Problem

To put the magnitude of EV battery waste into perspective, in 2019, China recycled over 60 metric tonnes of lithium-ion batteries and cornered over 70% of market share in the battery recycling market. South Korea is in the second position recycling just under 20 metric tonnes of used batteries.

The high cost of energy and the mounting e-waste problems led China to concentrate on battery recycling. The battery recycled market in China is dominated by CATL, BYD and Guoxuan High-Tech.

German multinational BASF is also a major player in lithium-ion battery recycling, while Belgian mining company Umicore also recycles EV batteries for Tesla and Audi cars.

India is not yet focussing on battery recycling, which could be a big gap in the market. As EV sales are expected to rise, India needs to be ready for the first wave of used batteries and those upgrading to newer EV models.

Indian battery manufacturers and startups have to step up and collaborate to solve this problem. Even, the electricity demand is increasing in India, hence the operational costs of EVs will increase in the coming years. India can control rising electric energy costs by recycling battery materials and reusing batteries.

India Cannot Afford To Ignore Battery Recycling

India is in the very early phase of EV adoption but will start facing problems from 2021 onwards when the first batch of EVs in the market will be at the end of their life cycles. In India, there is no large battery recycling plant.

The end life of batteries also impacts sustainability and the value chain of materials. The end-use problem of the battery can be solved by reusing and recycling. With reuse and recycling, the demand for battery materials can be controlled. Otherwise, the price of battery materials will continue to rise with the rising demand for EVs.

Suzuki, Toshiba and Denso formed a partnership in 2018 to manufacture lithium-ion batteries in India. In the initial phase, the consortium invested INR 1214 Cr to produce lithium-ion batteries which are expected to be in production by 2020. In the next phase, it is investing INR 4930 Cr and working with the Gujarat government on recycling of materials such as lithium, nickel, cobalt and manganese.

Tata Chemicals started operations of a battery recycling plant near to Mumbai in September 2019 and is trying to scale up battery recycling to 500 tonnes per year. The company is also investing INR 400 Cr to build a 10 GW lithium-ion battery plant at Dholera in Gujarat.

Mahindra Electric is also interested in setting up a battery manufacturing plant with a recycling facility. The partnership with large battery manufacturers will help it realise this plan. The other companies which are working in the battery manufacturing and recycling field in India are Exicom Tele-Systems, Relicell Battery, and Exigo Recycling.

Opportunities In Second-Use Of Battery

The reuse of batteries after being removed from EVs is gaining more attention today with an increasing number of EV sales. As per the National Renewable Energy Laboratory (NREL), a battery’s second life can be extended for up to 25 years. Generally, EV batteries have a lifetime of 8-10 years. After that, the capability of the battery is not completely diminished. Hence, there is a huge opportunity for the second-use of a battery in low-grade applications

The electric battery can be reused for stationary storage applications such as power backups, renewable energy storage and off-peak energy storage before being disposed of. However, there are plenty of challenges in the second use of batteries as well. There is no proper regulation and standards for such use-cases and only the synergistic efforts of government and industry players will be able to address these issues.

In the future, a more robust value chain will be created among automakers, EV owners, utility players and battery manufacturers for the second use of battery applications. This should significantly reduce the cost of EVs and bring price parity with conventional vehicles.

Lessons From China’s Mistakes

At the start of the 21st century, Chinese EV manufacturers used to dump two-wheelers past their life cycles, along with their batteries. Manufacturers were not taking the initiative to recycle battery materials as this was a more costly exercise than making new two-wheelers. It started creating heavy metal poisoning of the groundwater and forced China to institute an e-waste recycling policy, along with a regulatory authority.

China is also the largest smartphone manufacturer in the world with every global brand manufacturing unit in the country. The expertise of battery recycling by smartphone makers has helped EV players as well. India can also look to take the help of the smartphone manufacturing industry to recycle and reuse vehicle batteries.

The Indian automotive industry is already running on low for over a year. The Covid-19 pandemic has already forced automakers to shut down production and rethink their supply chain. Even the mobility business is impacted gravely, halting sales of fleet cars and bikes.

Indian automakers can focus on developing battery recycling technology and second-use of battery applications in the interim through market research and studies. This is the time to rethink the EV vision for India and come up with forward-looking solutions for the real big problems. DataLabs By Inc42’s Electric Vehicle Market Outlook Report highlights exactly which areas the EV industry can focus on even as Covid-19 and coronavirus have disrupted life.

At the initial stage of EV adoption, automakers are struggling to reduce the price of EVs as the scalability of production is not achieved yet and EVs are not yet appealing brands. Alternative models such as recycling and reusing can help achieve it just a bit faster.

ORDER YOUR COPY NOW!Note: We at Inc42 take our ethics very seriously. More information about it can be found here.