Inc42 Daily Brief

Stay Ahead With Daily News & Analysis on India’s Tech & Startup Economy

Advancing 3-D technology has led to its entry in medicine also. 3-D scanning technologies have well known applications in architecture, manufacturing and engineering.3D printing or additive manufacturing is a process of making a three-dimensional solid object of virtually any shape from a digital model.

3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes. 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes).

A 3D printer is a limited type of industrial robot that is capable of carrying out an additive process under control. The birth of 3-D scanning technologies combined with organic inks and thermoplastics has enabled the “bio printing” of a range of human body parts to accommodate a wide range of medical conditions. Scientists are now 3-D printing body parts ranging from plastic skulls to artificial eyes.

Following are the inventions by different research universities in the field of medicine using 3-d scanning techniques

1.) Washington State University has 3-D printed structures from layers of bio-compatible calcium phosphate, including a hip stem (left) and bone scaffolds.

2.) Robohand has collaborated with American Mike Ebeling to provide affordable printed arms to war amputees in Sudan.

3.) South Africa’s Robohand 3-D prints cheap mechanical prosthetic hands, arms and fingers.

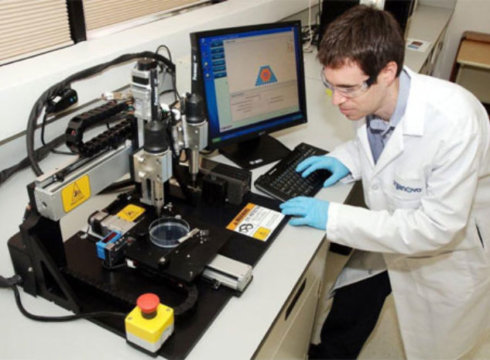

4.) Wake Forest School of medicine in the United States is developing a printer that will print skin straight onto the wounds of burn victims. Pictured, a researcher works on a prosthetic “burned” hand.

5.) Doctors at University Medical Center Utrecht, in Holland, completely replaced a patient’s skull with a 3-D printed plastic version.

6.) Lawrence Bonassar, of Cornell University, has created ears made from living cells, grown from 3-D printed molds.

7.) Fripp Design is also 3-D printing prosthetic ears, made from pigments, starch powder and silicone.

8.) Fripp Design and Research and Manchester Metropolitan University are able to 3-D print up to 150 prosthetic eyes an hour.

This technical boom has revolutionized the process of providing options to disabled and crippled. Person without legs will now be able to walk using starch made legs. Person with wounded skin will now be able to replace that part of skin. Patients with bone-fractures will now be able to heal in few days by using a special bone-like structure that acts as a scaffold for new bone cells to grow on, before it degrades.

Note: We at Inc42 take our ethics very seriously. More information about it can be found here.